When John Cadwell recognized the need for hollow fiber bioreactor solutions for laboratory cell culture requirements he capitalized on his idea. In March 2000, Cadwell founded FiberCell Systems, which over the last two decades has supplied hollow fiber bioreactors to the biomedical research and development community. “Hollow fiber bioreactors are ideal for culturing a lot of cells in a small space and collecting what they secrete such as antibodies, recombinant proteins and extracellular vesicles,” explained Cadwell, CEO. “Hollow fiber bioreactors present a unique, 3-D cell culture environment and permit the culture of large numbers of cells at high densities, while representing the most ‘in vivo’ like way to grow cells,” he continued.

When John Cadwell recognized the need for hollow fiber bioreactor solutions for laboratory cell culture requirements he capitalized on his idea. In March 2000, Cadwell founded FiberCell Systems, which over the last two decades has supplied hollow fiber bioreactors to the biomedical research and development community. “Hollow fiber bioreactors are ideal for culturing a lot of cells in a small space and collecting what they secrete such as antibodies, recombinant proteins and extracellular vesicles,” explained Cadwell, CEO. “Hollow fiber bioreactors present a unique, 3-D cell culture environment and permit the culture of large numbers of cells at high densities, while representing the most ‘in vivo’ like way to grow cells,” he continued.

Located just outside Frederick, Maryland, FiberCell Systems is a small, agile organization with its own laboratories and facilities to perform proof of principle studies. They discovered that the cell culture conditions permitted by their hollow fiber bioreactor are different enough from other methods of cell culture that it permits the use of simplified, optimized, protein free medium to be used; leading to the creation of CDM-HD, which permits the culturing of cells at high densities.

The FiberCell system permits the culture and harvest of extracellular vesicles, in addition to producing large quantities of cells in its bioreactors. Extracellular vesicles have demonstrated regenerative capabilities and are what Cadwell believes to be the “prime therapeutic vector in many stem cell transplant studies.” The hollow fiber bioreactors that his company provides represent a viable solution for getting extracellular vesicle therapies to the clinic in a closed, cGMP compliant system. A single C2011 Medium Sized Cartridge from FiberCell Systems can produce as many extracellular vesicles as 500 T225 flasks in a significantly smaller volume.

Cadwell believes producing cGMP quality extracellular vesicles at clinical scale represents a major barrier that needs to be overcome in the next 5-10 years within the industry. “Everyone that I talk to in the extracellular vesicle field knows that the ability to generate cGMP quality exosomes in clinical amounts represents major barrier to their development and application,” he said. “Many grants are turned down due to the lack of defined capability and capacity.”

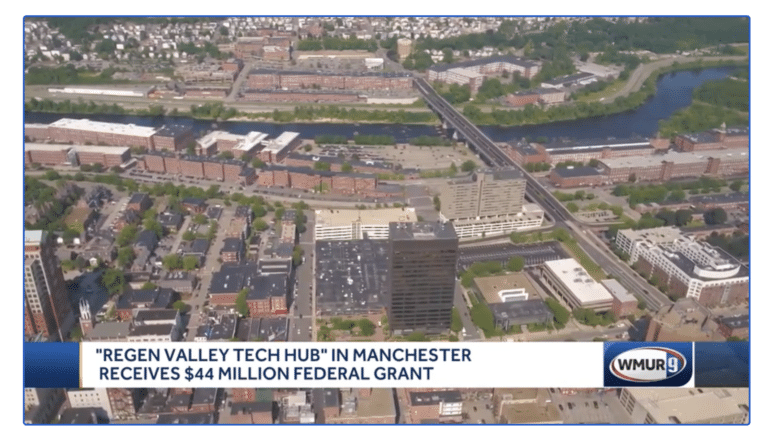

Cadwell sees ARMI | BioFabUSA as being able to bring together companies and facilitate product application and development outside the traditional biotech funding paradigm, where biotech companies are funded by investment based on a patent portfolio. Additionally, by joining the ARMI | BioFabUSA community, Cadwell believes he and his company will be able to “generate greater awareness of hollow fiber bioreactors and their capabilities to the regenerative medicine community as a whole. Even though the technology is old, over 40 years, there is still not a lot of awareness of what it is and what it can do.”

With years of experience in 3D hollow fiber cell culture, FiberCell Systems is actively seeking new applications to take advantage of the specific 3D cell culture properties of their unique bioreactor system. “At FiberCell Systems, we recognize that it is not all about the products that we sell, but about the service and technical support that we provide. We pride ourselves in being a partner in the advancement of a company’s research.” For more information, be sure to check out FiberCell Systems.