Technical Projects

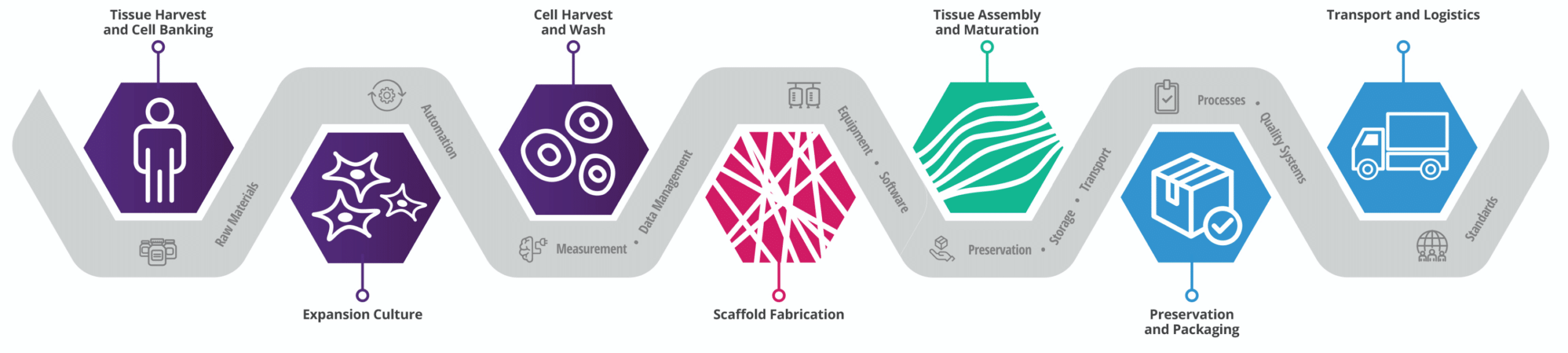

BioFabUSA’s Technology Development Projects are intended to fill current manufacturing technology gaps. The solutions we develop are interoperable with each other, as well as existing technologies, enabling scalable, consistent and cost-effective manufacturing. Technical project calls and approved projects span the manufacturing process and crosscutting development areas from our technical roadmap.

Strategic Priority Areas

Strategic priority areas for Technology Development Projects are outlined in the BioFabUSA Technology Roadmap. We identified as strategic priority areas the following activities, which cut across the manufacturing process for cells, tissues and organs:

Raw Materials

Tighten control over raw materials

Equipment & Software

Develop equipment that enables automation of manual or high-risk process steps

Automation

Develop advanced automation that minimizes process variability and labor costs

Measurement & Data Management

Design and implement measurement technologies that integrate with technologies and methods to store, manage and integrate large volumes of data

Preservation, Storage & Transport

Advance technologies and processes for the preservation, packaging and transport of process-intermediate and final product

Processes & Quality Systems

Demonstrate and promote a Quality-by-Design-based (QbD) approach to process development and manufacturing

Standards

Support the development of relevant standards

Tech Development Across the Manufacturing Process

Technology Development Projects span end-to-end manufacturing of cells, tissues and organs—from the point of cell or scaffold harvest as a raw material input to the transportation of the final product.

Example Projects

Kristen Billiar, professor of biomedical engineering and mechanical engineering at Worcester Polytechnic Institute (WPI) and head of WPI’s Department of Biomedical Engineering, on creating a system for non-destructively and non-invasively measuring the mechanical properties of tissue-engineered medical products.

Hsueh-Chia Chang, Bayer Professor, Chemical and Biomolecular Engineering at Notre Dame, on overcoming the obstacle of monitoring, in real-time, the health and identity of cells growing in a bioreactor.

Jay Hoying, Chief Scientist at Advanced Solutions, on employing a robotic arm-based platform to achieve greater efficiency and consistency to automate regenerative manufacturing process steps.

BioFabUSA Technical Project Calls

A major objective of ARMI | BioFabUSA’s technology strategy is to develop platform technologies to remove existing hurdles to scalable, consistent and cost-effective tissue manufacturing of cells and organs. The prototype for this approach is the ARMI | BioFabUSA Tissue Foundry, a scalable, modular, automated and closed manufacturing platform. We developed it to demonstrate advanced manufacturing for cells, tissues and organs, as well as to anchor the development, validation and demonstration of new technologies across ARMI | BioFabUSA’s crosscutting development areas.

To access previous project calls: